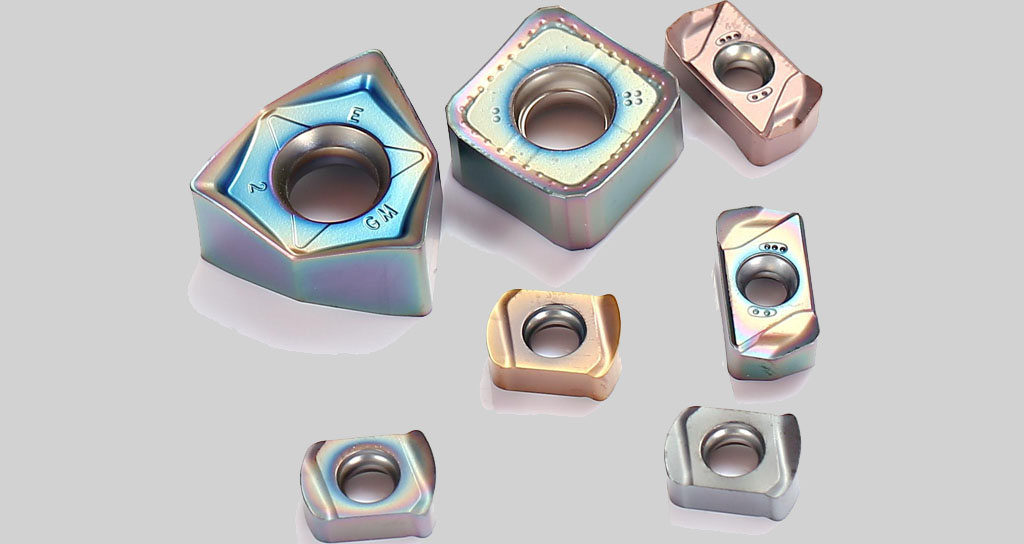

High Feed Inserts are specialized milling inserts designed for use in High Feed Milling (HFM) applications—where very high feed rates and shallow depths of cut are employed to maximize material removal rates. These inserts are typically mounted on high-feed cutter bodies engineered with low lead angles, which direct cutting forces axially into the spindle, enhancing stability and tool life.